SPACE November 2025 (No. 696)

The construction and architecture sectors currently account for the highest level of carbon emissions of all industrial fields worldwide. Architecture, which has supported humankind for ten thousand years, entered the twentieth century with efficiency and economy as supreme values, adopting concrete and steel almost exclusively as its materials. In this context, as the world has experienced a pandemic and is facing an environmental crisis, an innovative critical approach has emerged to redefine the concept of sustainability. Specifically, the use of organic-based composite materials suggests a new possibility for architecture, which has long depended on inorganic materials that cannot be recycled or decomposed. By presenting experiments using the mycelial body of mushrooms – an organism that plays a filtration role in our ecosystem – this project reinterprets the concept of eco-friendly architecture and demonstrates the potential of innovative bio-integrated fabrication methods.

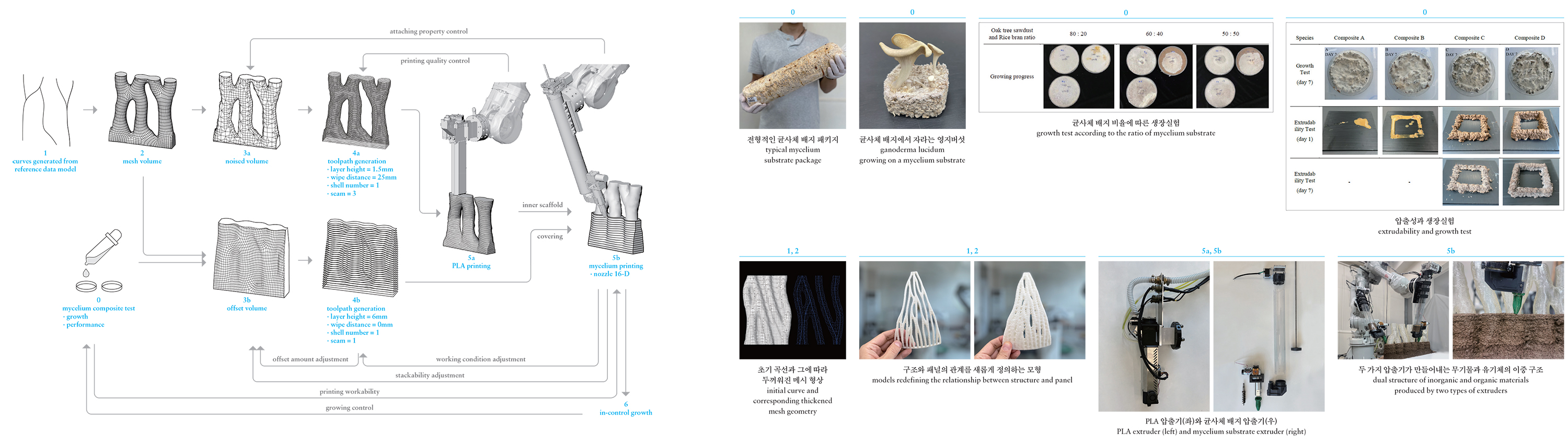

Workflow for hybrid mould fabrication integrating mycelium and printing

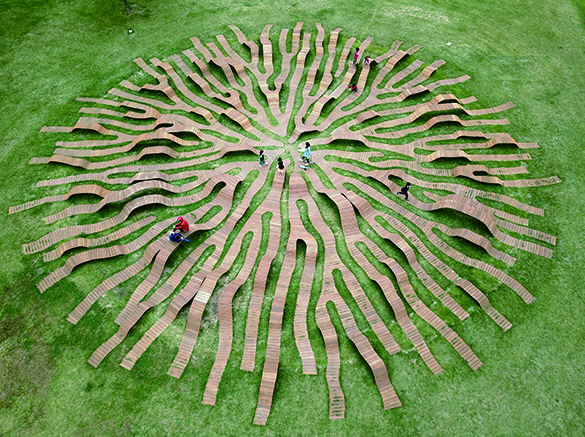

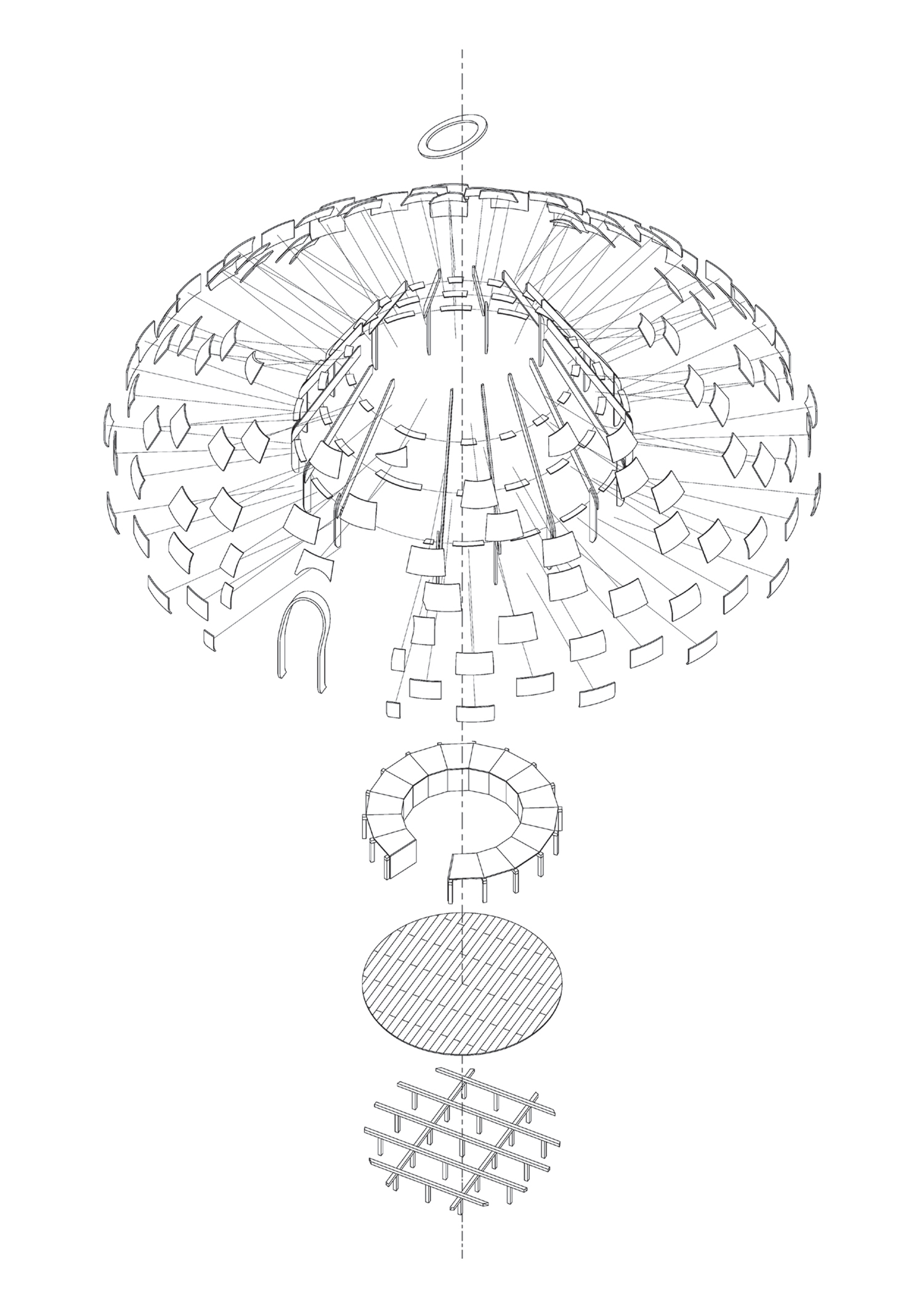

MMycelial Hut (2025) aims to scale up the application of mycelium as an architectural material through customised moulds combined with robotic 3D printing technology. This design-based research explores a bio-hybrid pavilion in which a timber frame performs a structural role, supporting custom mycelium panels that form the outer skin system. In the early stages, various types of mycelium substrates were tested to determine their workability, while assessments of growth behaviour, strength, and moulds were produced using 3D printing technology based on these results. Ultimately, a new workflow integrating an industrial robotic arm was established, enabling the creation of a large-scale structure that merges digital fabrication with natural growth processes. The pavilion project addresses challenges associated with fungal applications and demonstrates the potential of biocomposite materials for architectural construction at scale. Situated on the campus of Seoul National University of Science and Technology, the project presents a bold outcome that embodies a new concept within sustainable architecture in everyday life.

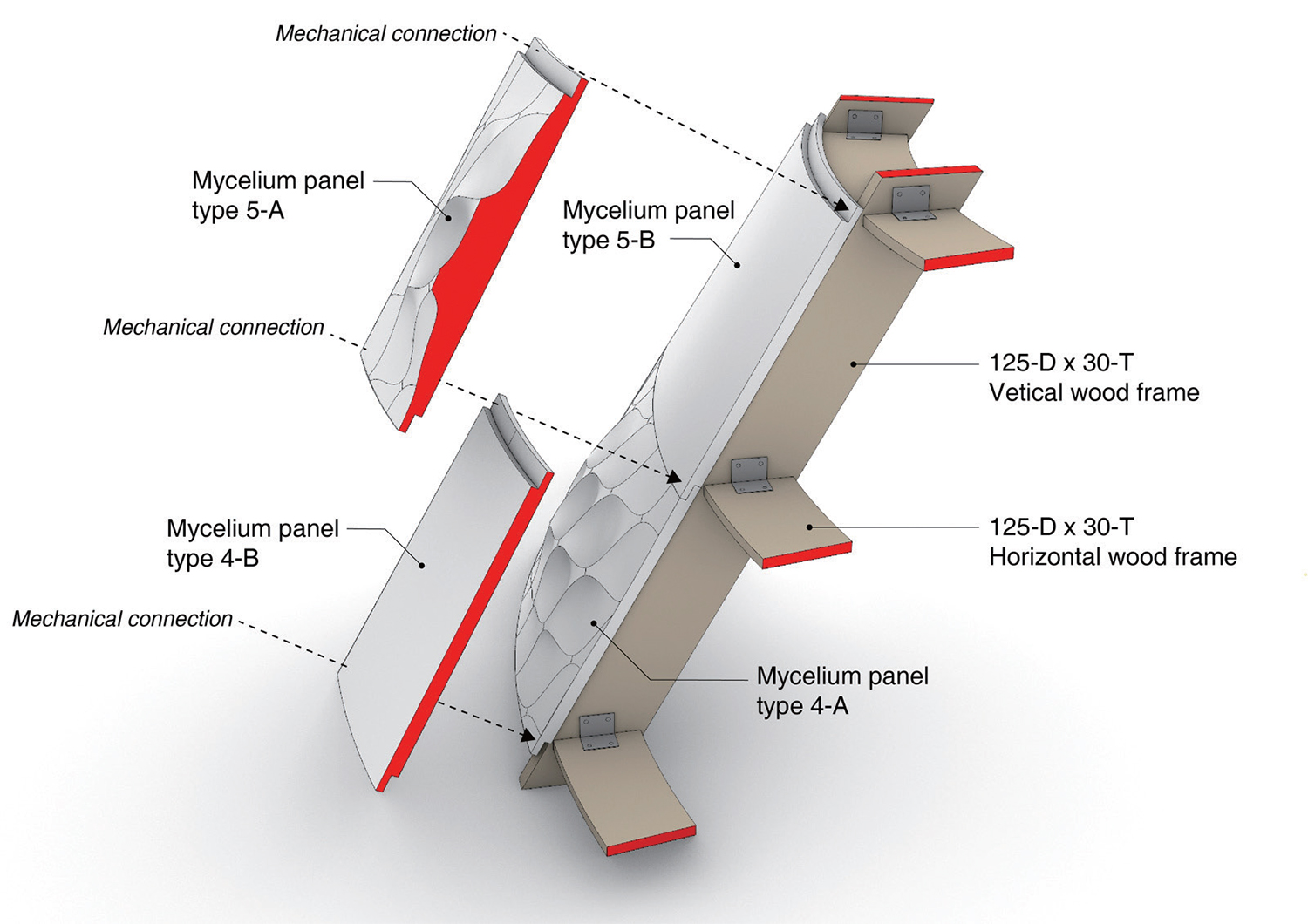

Detail diagram of panel joints

On-site assembly process

Yong Ju Lee Architecture (Yong Ju Lee)

Oh Dachan

232, Gongneung-ro, Nowon-gu, Seoul, Korea

pavilion

10㎡

10㎡

3.7m

wooden frame

July – Sep. 2024

Sep. – Dec. 2024

5 million KRW

EarthForm

Robotic Fabrication Studio (Oh Dachan, Kim Hakjoon